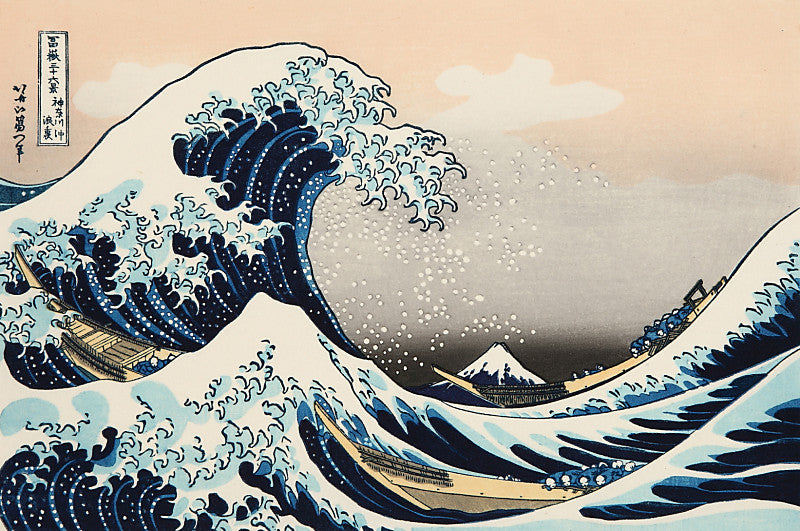

⚫︎Until woodblock Ukiyo-e completed

The reproduced edition woodblock print Ukiyo-e has the same distinctive vividness and texture that people in the Edo period had. We are explaining how Ukiyo-e is produced and the work that matured skilled craft workers in the modern time who are succeeding the craftsmanship from the Edo period.

The quality has been proven since we started marketing the products with no unsatisfactory returns and claims, and we have many returning customers.

“Carving” is cutting woodblock with matured techniques. This process starts with the procedure deciding how many blocks will be necessary to use after the masters observe the painter’s draft. This process starts with the procedure deciding how many blocks will be necessary to use after the masters observe the painter’s draft

Each reproduction of one reprint edition of woodblock print Ukiyo-e starts the same process: The woodcarver starts carving the wood decoding the picture that the painter worked. Then, the woodprint-rubbing master repeats painting several colors onto the Japanese paper wising the original woodblocks. One integrated teamwork from three masters, such as painters, woodcarvers, and woodprint rubbing masters and a publisher as a producer, created an Ukiyo-e.

Publisher (Chief producer) painter → woodcarver → woodprint-rubbing → master